Intimate service comes from the recognition of customers, and proposes high-quality product matching solutions according to customer needs

Product quality comes from rigorous and perfect quality control, and every step is full of our strict sense of responsibility

Exclusive customization comes from personalized configuration solutions, timely and efficient supporting new product development and production

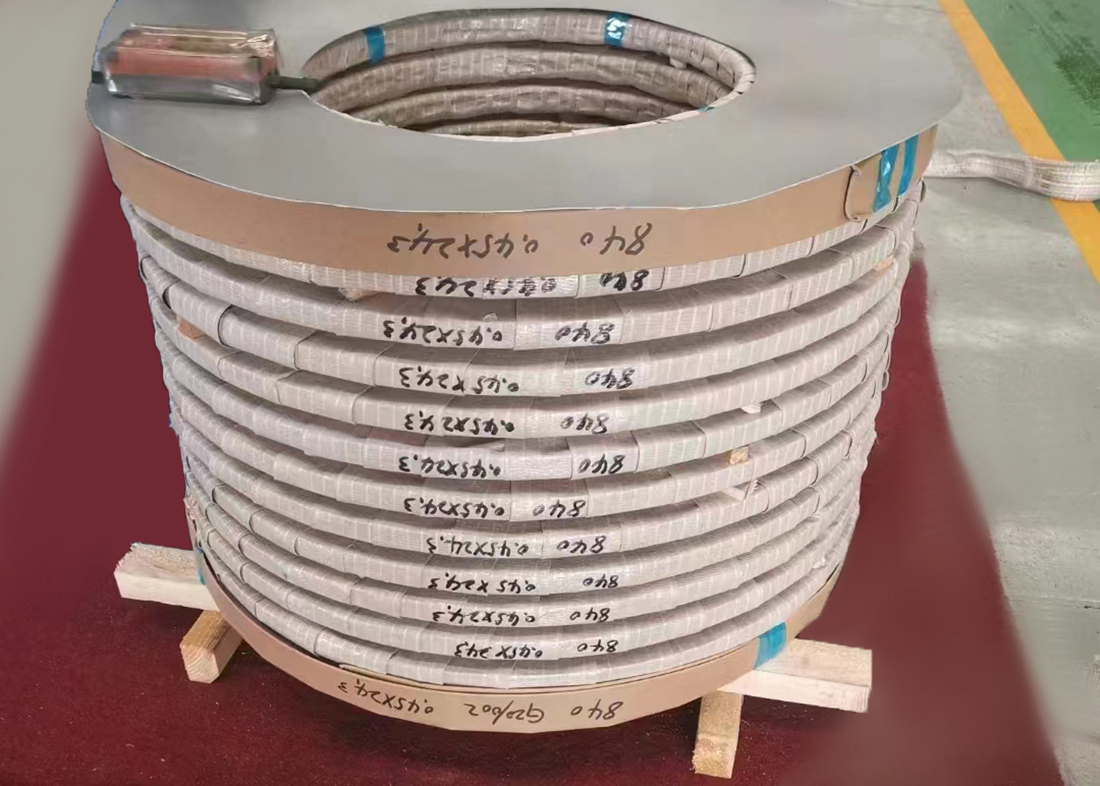

Fast distribution originates from sufficient inventory + processing + fast logistics, and upholds enthusiastic and efficient management

From raw material detection to warehousing registration management, to ensure the overall quality of products

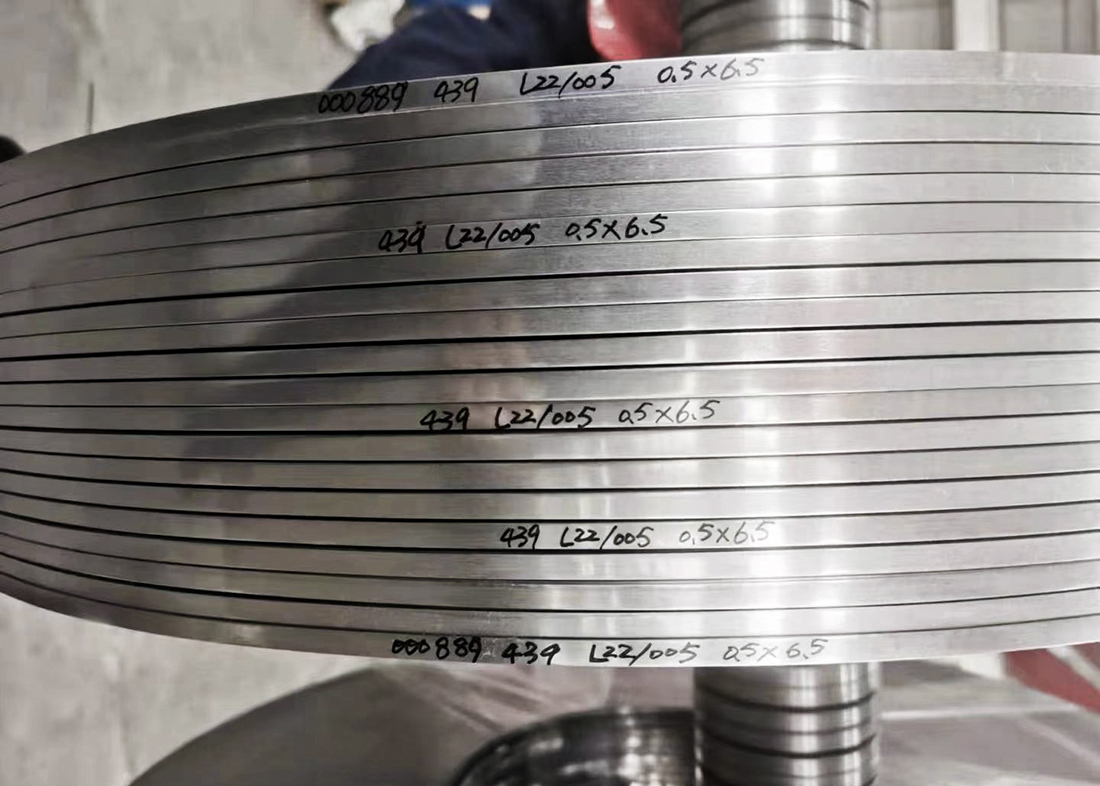

From surface treatment to standard comparison

From material cutting and processing control to re-inspection, packaging and delivery

Every step is full of our strict sense of responsibility

Special material stainless steel is mainly produced with a thickness of 0.02mm-3.1mm and a width of 1mm-1500mm

Relying on the company's domestic and foreign processing equipment and logistics network throughout the country

From customer orders to fit stock screening

Then to processing, production, re-inspection and distribution

Our R&D team has established good cooperative relations with domestic and foreign steel mills

Timely and efficient cooperation with customers for product development

Combined with a Japanese-funded continuous electroplating factory, we have successfully launched gold-plated, silver-plated, nickel-plated and other electroplating products.

Products have broad market prospects and development potential

Heavy equipment (such as construction machinery, mining equipment, port machinery, wind power equipment, etc.) operates under harsh conditions, enduring heavy loads, corrosion, high and low temperatures, and other challenges. Stainless steel coils, with their comprehensive advantages of high strength, corrosion resistance, formability, and durability, have become the material of choice for key com

Stainless steel strip is a strip-shaped stainless steel product made from stainless steel billets as the core raw material, processed through processes such as hot rolling, cold rolling, and finishing. Its core raw material is the stainless steel base material, and the composition ratio of the base material determines the key properties of stainless steel strip such as corrosion resistance, streng

The functional processing technology of stainless steel coils is to endow the basic material with exclusive functions such as rust prevention, wear resistance, aesthetics, conductivity/insulation, etc., to meet the special usage needs of different industries. The technology is mature and highly targeted. The specific classification and details are as follows:

The surface treatment of stainless steel strip is a key process to improve its corrosion resistance, aesthetics, and processing adaptability, and the corresponding treatment process needs to be selected according to downstream application scenarios (such as home appliances, electronics, precision machinery). The following are common surface treatment methods, process characteristics, and applicabl

Stainless steel coils are one of the core raw materials in the home appliance industry due to their strong corrosion resistance, smooth and easy to clean surface, stable mechanical properties, and durability. They are widely used in the structural, appearance, and functional components of various home appliances such as refrigerators, washing machines, water heaters, and kitchenware. According to

The engineering equipment industry covers multiple sub sectors such as chemical engineering, energy, construction engineering, and rail transit. Stainless steel coils, with their characteristics of corrosion resistance, high strength, and easy processing, can be processed into various structural components, containers, accessories, etc., suitable for complex working conditions of different enginee

Stainless steel coils are widely used in various equipment manufacturing, pipeline systems, container lining and other scenarios in the chemical industry due to their excellent corrosion resistance, high temperature resistance, strength and processability. They are the core material for dealing with complex media (such as acids, alkalis, salts, organic solvents, etc.) and harsh working conditions

1. Different production processes Stainless steel hot rolling is rolled above the recrystallization temperature of the metal material, and stainless steel cold rolling is rolled below the recrystallization temperature of the metal material, and each metal material has its own recrystallization temperature. crystallization temperature.

Heavy equipment (such as construction machinery, mining equipment, port machinery, wind power equipment, etc.) operates under harsh conditions, enduring heavy loads, corrosion, high and low temperatures, and other challenges. Stainless steel coils, with their comprehensive advantages of high strength, corrosion resistance, formability, and durability, have become the material of choice for key com

Stainless steel strip is a strip-shaped stainless steel product made from stainless steel billets as the core raw material, processed through processes such as hot rolling, cold rolling, and finishing. Its core raw material is the stainless steel base material, and the composition ratio of the base material determines the key properties of stainless steel strip such as corrosion resistance, streng

The functional processing technology of stainless steel coils is to endow the basic material with exclusive functions such as rust prevention, wear resistance, aesthetics, conductivity/insulation, etc., to meet the special usage needs of different industries. The technology is mature and highly targeted. The specific classification and details are as follows:

The surface treatment of stainless steel strip is a key process to improve its corrosion resistance, aesthetics, and processing adaptability, and the corresponding treatment process needs to be selected according to downstream application scenarios (such as home appliances, electronics, precision machinery). The following are common surface treatment methods, process characteristics, and applicabl

Stainless steel coils are one of the core raw materials in the home appliance industry due to their strong corrosion resistance, smooth and easy to clean surface, stable mechanical properties, and durability. They are widely used in the structural, appearance, and functional components of various home appliances such as refrigerators, washing machines, water heaters, and kitchenware. According to

The engineering equipment industry covers multiple sub sectors such as chemical engineering, energy, construction engineering, and rail transit. Stainless steel coils, with their characteristics of corrosion resistance, high strength, and easy processing, can be processed into various structural components, containers, accessories, etc., suitable for complex working conditions of different enginee

WeChat ID:m.yhdc888.com

WeChat ID:m.yhdc888.com